Supply Chain Management is often a misunderstood or ignored matter in Bangladesh. Many organizations here are concerned about customer outreach or sales growth only, whereas demand planning or demand uncertainty planning is not given the needed attention. Thus, the supply chain becomes only a procurement and logistics-dependent function in these organizations.

In modern days, creating demand is a part of the marketing concept, and fulfillment of that demand is a part of the supply chain concept. Fulfilling any customer’s demand can be very simple – just buy or collect a product and deliver it to the customer. In any small-scale operation, it may work efficiently. However, in a large-scale operation with thousands of orders, the products need to be sold through distributors and retailers.

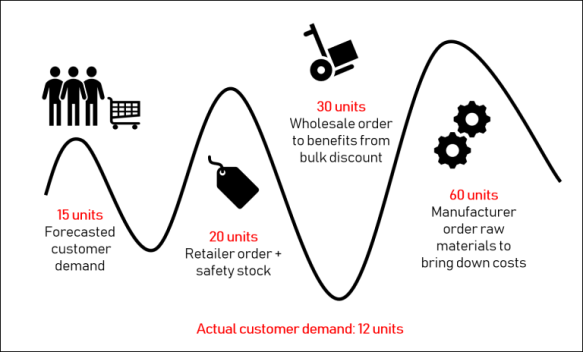

Now the point comes to how the seller can get the correct information regarding the customer demand. If the information is wrong, then it can create a bullwhip effect. It is a phenomenon in which small fluctuations in demand at the retail level can cause progressively larger fluctuations in demand at the wholesale, distributor, manufacturer, and raw material supplier levels. To mitigate this problem, industries arrange regular meetings with Sales and Operation Planning (S&OP), Supply Chain Management (SCM), and the Sales team.

Bangladesh is a developing country, where various industries are growing continually. Yet the practice of supply chain management is not growing at the same rate with proper functionality. A well-established supply chain system can increase revenue growth and gross as well as net profit. With good profitability, the organization can grow further by investing in new plants or new projects. Let’s say, a biscuit company plans for BDT 100 crore annual sales target with a 40 percent gross profit margin. To fulfill this, the SCM team plans for procuring raw material (RM), packing material (PM), logistics, inventory, warehouse, transportation, manufacturing, low-cost labor, demand uncertainty, global sourcing, and short-term financing with competitive rates. All these together are called Cost of Goods Sold (CoGS), which are kept at BDT 60 crore to ensure a 40 percent gross margin. If the company obtains a 10 percent net profit margin, it means that after excluding all the costs, such as operating expenses, interests, and taxes, the final profit is BDT 10 crore. With this net profit, the company can plan for a new factory or expand the existing factory with or without a bank loan.

A supply chain can either build or destroy a business. Two of the most important competitive differentiators – price and customer experience – are governed by the way a business manages its supply chain. A single disruption can trigger a series of uncertainties and inefficiencies across the supply chain. Imagine shipping steel to a construction contractor within a certain time frame. If the delivery gets delayed by a single day only due to some reason and the customer is not made aware of this delay, it creates a domino effect. The contractor’s arranged manpower for a day will be completely wasted. The next set of people who are supposed to take over the task from the first team has to wait for another day, which they may or may not agree with. This is how the hours keep adding up and the estimated time to complete the construction may go way beyond the budgeted time.

The supply chain has been facing challenges all over the world since the beginning of Covid 19. Multiple city and country-wide lockdowns slowed down or even temporarily stopped the flow of raw materials and finished goods, disrupting the manufacturing processes. Many organizations suffered from staff shortages and losses. The Russia-Ukraine conflict and renewed COVID-19 lockdowns in China have recently worsened these issues, even more, affecting supply in various sectors including consumer goods, metals, food, chemicals, and commodities. The embargo imposed on Russia continues to impact fuel costs, as well as freight markets and global logistics. This is causing a significant impact on Bangladesh’s economy as well. Only 4 months after declaring 100 percent of people under electricity coverage in March 2022, the government had to impose load shedding from July 2022. The main reason behind this continuing electricity problem is the fuel crisis, for which Bangladesh is heavily dependent on imports from various countries. This ongoing crisis is a perfect example of supply chain failure.

In the backdrop of such unprecedented challenges, what measures should be taken? Suppliers all across the world are struggling to keep their commitments. Hence, we must search for alternative suppliers, raw materials, or products wherever possible so that during a crisis if one fails to deliver, we have a backup plan in place. Sufficient flexibility shall be built for protection against future disruptions. A robust framework shall be developed including a responsive and resilient risk management operations capability. It should also ensure end-to-end transparency across the supply chain.

Engr. Md. Mazharul Hossain is a Certified Supply Chain Manager (CSCM), working as Project Logistics Controller at Toshiba Energy Systems and Solutions Corporation.

Such a nice and informative article, points briefed in it are very true and I strongly do agree with them.

Thanks

Such a informative & Instructive Article.

Thanks