Whenever we hear about whey an image of bottled product comes to our mind, which is mostly consumed by athletes and bodybuilders as a source of high-quality protein for strength, muscle growth as well as repair, and performance enhancement. But where is this whey originated from?

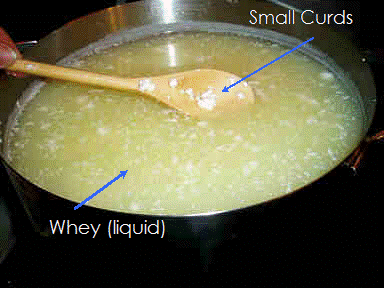

When cheese or chana is made, the milk protein (casein) coagulates, and a yellow-greenish watery liquid is separated as a byproduct, which is known as whey.

Whey is an abundantly produced by-product of the dairy processing industry including cheese, chana, sweetmeats, and paneer production. It accounts for about 85 to 90 percent of the milk volume and contains about 55 percent of the milk nutrients.

The Department of Livestock Services of the Government estimates that 11.98 million metric tons of milk were produced in Bangladesh during the 2020–21 fiscal year. Based on the literature studies, it is found that approximately 30 percent of these go to the dairy processing industry, which results in the annual production of more than 3 million metric tons of whey. This whey is mostly dumped in the surroundings.

Whey is regarded as the most significant environmental contaminant of the dairy sector because a large amount of whey is disposed of as wastewater and is linked to serious environmental hazards. With low biodegradability and high biological oxygen demand (BOD) value, whey disposal is extremely harmful and toxic if it is discharged without proper treatment. If whey is poured in one spot, it will create a subsoil layer, which is bad for the soil – plants will not grow there.

Hence, it is important to direct whey management towards a cost-effective and sustainable production of valuable products to utilize whey’s nutritional value. Whey proteins constitute about 20 percent of the total proteins present in milk. It is also a rich source of vitamin B, minerals (calcium, Phosphorous, sodium, potassium, chloride, iron, copper, zinc, and magnesium), and lactose.

There are numerous approaches to sustainable whey management, most of which are focused on biotechnological and food applications for the creation of value-added products such as whey powder, functional foods, and beverages, lactic acid, bioethanol, bioplastics, biogas, etc.

The creation of whey powders is one of the most often-used methods of utilizing liquid whey. This large-scale industrial process consists of several steps, almost as similar to that of producing milk power from liquid milk, including –

-

Whey clarification

-

Cream separation and pasteurization

-

Total solids concentration (40 to 60 percent by evaporation)

-

Lactose crystallization

-

Whey drying (removal of water by spray drying).

The most common use of whey powder products is as an additive in the production of a wide variety of foods and beverages (e.g., infant formula, meat products, beverages, soups, sauces, toppings, etc.). However, due to the high nutritional value

The most cost-effective use of lesser amounts of whey in a small-scale production facility is to create fermented or unfermented whey-based beverages. A research team from the Dairy Microbiology and Biotechnology Lab at the department of Dairy Science at Bangladesh Agriculture University has been working in this respect and has formulated a viable probiotic dairy beverage using whey and pineapple juice. This can be stored for 6 to 7 weeks at a 4-degree Celsius temperature.

This probiotic whey-pineapple beverage can be a feasible way to control the dairy industry’s by-product while also providing a functional and nutritional drink for human consumption.

Md. Shahriar Islam Sojib is a dairy scientist